Why Conex Trailers Are Essential for Modern Container Transport

Conex trailers are specialized wheeled chassis designed to transport shipping containers efficiently and safely. Whether you’re managing a construction site, handling retail overflow, or coordinating logistics operations, understanding these trailers helps you move containers without expensive cranes or heavy equipment.

Quick Guide to Conex Trailers:

- What it is: A trailer specifically engineered to load, transport, and unload shipping containers (20ft or 40ft)

- Main types: Tilt-bed (hydraulic ground-level loading), Gooseneck (improved stability for long hauls), Chassis (simple flatbed design)

- Key benefit: Load/unload containers without cranes—many models tilt to ground level or use winch systems

- Typical capacity: 10,000-14,000 lbs GVWR with 10K or 12K axles

- Space needed: 60ft for 20ft containers, 100ft for 40ft containers

- Towing: Often compatible with 1-ton pickup trucks for empty containers

The history of these trailers traces back to the 1950s when the U.S. Military developed the “Container Express” (CONEX) box. This innovation reduced shipment times from 55 days to under 35 days during the Korean War. Today, over 95% of shipping containers worldwide are based on that original CONEX design.

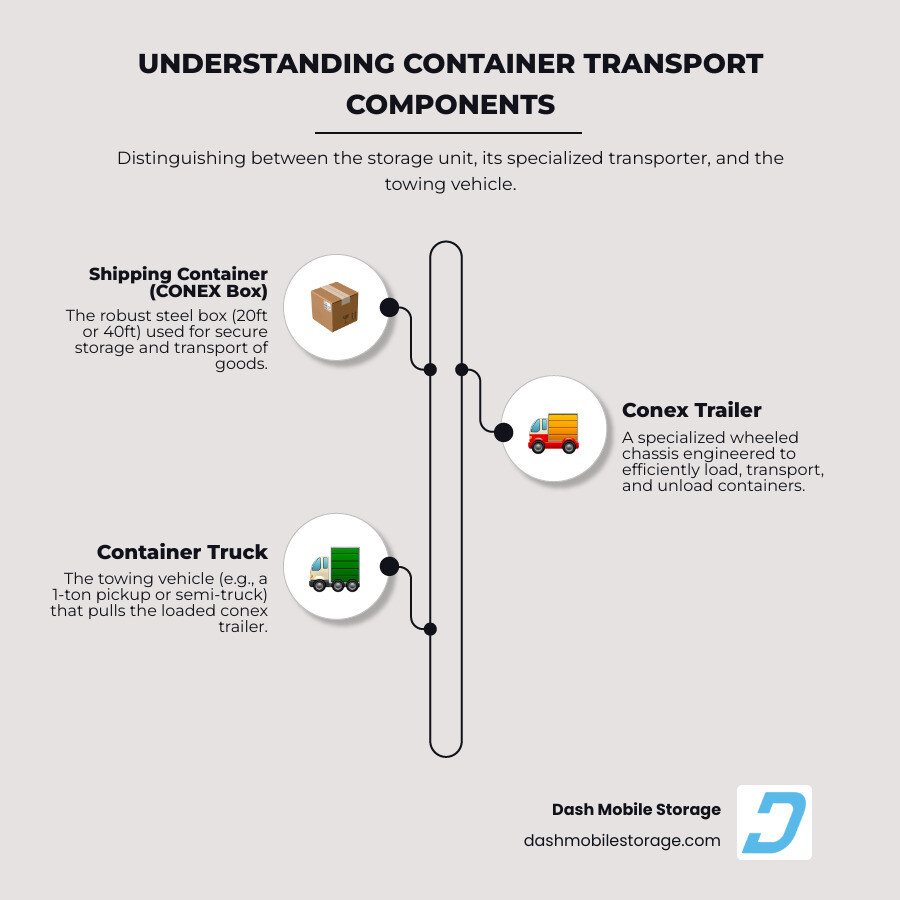

The difference matters: A shipping container (or Conex box) is the steel storage box itself. A Conex trailer is what moves it. A container truck is the vehicle that pulls the trailer. Understanding this distinction helps you choose the right solution for your project.

For construction project managers in South Florida, these trailers solve critical challenges—delivering secure on-site storage without disrupting job site operations, managing excess inventory during project phases, and providing mobile offices where traditional construction isn’t practical.

This guide walks you through trailer types, selection criteria, customization options, and the key factors that determine whether buying or renting makes sense for your specific needs.

The Evolution of Container Transport: From CONEX Box to Modern Shipping

The story of modern container transport, and by extension, conex trailers, begins not in busy commercial ports, but on the battlefields of World War II. The U.S. Military faced immense logistical challenges, with cargo delays causing significant losses of time, money, and vital resources. Imagine the frustration of waiting 55 days for essential supplies, only for much of it to be damaged or misplaced. This pressing need for efficient and safe transport spurred innovation.

In 1948, the U.S. Army began experimenting with reusable steel containers. These initial prototypes, referred to as “Conex boxes,” were quite compact, measuring around 8-by-6-by-6 feet and capable of carrying approximately 9,000 pounds. They featured practical elements like double doors on one end, liftd skids for easy movement, and lifting rings for crane operations. This was a pivotal moment, laying the groundwork for what would become a global standard.

The program quickly proved its worth. In 1951, an additional 100 transporters were commissioned for use by the Far East Command during the Korean War. The success was undeniable, leading to a formal rebranding in 1952 as the “Container Express,” or CONEX box. This development dramatically improved transportation times, slashing typical shipment durations from 55 days to under 35 days. It was a game-changer for military logistics.

The versatility of CONEX boxes was further highlighted during the Vietnam War, where they were not only used for delivering supplies and spare parts but also ingeniously repurposed. They served as makeshift command posts, sturdy bunkers, and even mobile medical dispensaries, demonstrating their robust construction and adaptability far beyond simple storage.

The military’s innovation soon caught the attention of the private sector. Shipping companies began designing ships specifically to transport these modular units, paving the way for the intermodal container system we know today. This era marked a crucial step towards standardization, which culminated in the establishment of the ISO standard for shipping containers—a standard largely based on the original CONEX box design.

The impact of this military-born innovation on global trade is staggering. Today, over 95% of shipping containers used worldwide are partially or entirely based on the Conex box design. It’s a testament to the foresight and ingenuity born out of necessity. For those keen to dig deeper into this fascinating history, the U.S. Army Transportation Museum offers a wealth of information. The Conex box truly revolutionized how goods move across the globe, making efficient transport a reality for businesses of all sizes, including our own operations right here in South Florida.

Understanding Conex Trailers and Container Transport

When we talk about conex trailers, it’s important to clarify what we mean and how they fit into the broader world of container transport. At its core, a conex trailer, also widely known as a shipping container trailer, is a specialized piece of equipment engineered specifically for the effortless loading, unloading, and transportation of shipping containers. Think of it as the sturdy, mobile platform that gives a stationary container the ability to travel.

This brings us to a crucial distinction often confused: the difference between a conex trailer and a container truck. A shipping container itself is the large, steel box designed for storage or shipping cargo—often called a Conex box or sea box. A conex trailer is the chassis, the wheeled frame, that carries this container. And finally, a container truck refers to the heavy-duty vehicle, like a semi-truck or even a robust pickup, that pulls the conex trailer (and its cargo) from one location to another. So, while a truck might be part of the “container transport” equation, the conex trailer is the dedicated component designed to interface directly with the container.

These trailers are foundational to intermodal transport, allowing containers to seamlessly transition between ships, trains, and roads. Their design ensures that once a container is loaded onto a trailer, it can be securely transported across various terrains, from busy ports to remote job sites in places like the Treasure Coast.

The construction materials and features of conex trailers and the containers they carry are chosen for durability and strength, built to withstand the rigors of heavy loads and diverse environments. Shipping containers themselves are typically made from Corten weathering steel, known for its exceptional resistance to corrosion, making them wind and water-tight. This material is used for the wall panels, frames, and cargo doors, ensuring the contents remain secure and protected.

For the conex trailers themselves, high-strength steel is the material of choice for the main beam of the chassis. This robust construction is essential to support the immense weight of loaded containers. Our research shows that many trailers are equipped with two 10,000# axles, often with electric brakes and dual wheels, providing the necessary load-bearing capacity and stopping power. These axle systems, along with sturdy suspension systems and tires (like 235/80/16 (E) 10 ply), are carefully constructed to comply with industry standards and meet stringent load requirements.

Safety is paramount in container transport. Therefore, conex trailers come equipped with critical features like electric brakes, which are essential for controlling heavy loads. An emergency breakaway kit with a built-in charger and battery level indicator adds an extra layer of safety, automatically engaging the brakes if the trailer detaches from the towing vehicle. Furthermore, D.O.T. reflective tape and LED lights ensure maximum visibility, especially during night-time operations on South Florida’s roads. These robust construction and safety features are what make conex trailers a reliable and efficient solution for businesses needing to move significant cargo.

Types of Conex Trailers and Their Applications

When it comes to moving shipping containers, not all conex trailers are created equal. The type of trailer you choose significantly impacts the ease, safety, and efficiency of your container transport. Here in South Florida, where diverse industries demand versatile solutions, understanding the different categories of conex trailers and their specific applications is key.

Generally, conex trailers can be categorized by their loading mechanism and design, with tilt-bed and gooseneck trailers being among the most popular and effective. Each type offers distinct advantages, making them suitable for various common uses and industry applications.

Tilt-Bed Trailers

Imagine needing to place a 40-foot container precisely on a job site without the hassle and expense of a crane. That’s where tilt-bed trailers shine! These specialized conex trailers feature a hydraulic tilt mechanism that allows the trailer bed to angle down to the ground. This ingenious design facilitates ground-level loading and unloading, making the process incredibly easy and efficient.

The heart of a tilt-bed trailer is often its 12-volt hydraulic pump with a twin-cylinder lift, which powers the seamless tilting action. This means containers can be smoothly rolled on and off the trailer, often with the assistance of a winch system. Many models come equipped with multiple winches, such as eight 4-inch winches on the sides, or a heavy-duty super-winch to haul containers onto the bed.

Construction-wise, tilt-bed trailers boast robust I-beam frame construction, with frames and necks often built from 12″ x 19# I-beams to handle heavy loads. They are ideal for job sites and on-site storage delivery, particularly in locations like Palm City or Fort Lauderdale, where quick deployment and retrieval of cargo storage containers are essential. The ability to load and unload without external heavy machinery makes them incredibly cost-effective and flexible for our clients.

Gooseneck Trailers

For those who need to transport containers over longer distances or require superior towing stability, gooseneck trailers are often the preferred choice. These conex trailers are distinguished by their gooseneck hitch design, which connects to a ball in the bed of a pickup truck (typically a heavy-duty one). This connection point, positioned over the rear axle, provides improved towing stability and better weight distribution compared to conventional bumper-pull trailers.

The gooseneck design inherently lowers the center of gravity of the combined truck and trailer, which translates to increased towing capacity and a smoother, more secure ride, especially when navigating highways between Miami and Stuart. Our research indicates that a 40′ Gooseneck Shipping Container Trailer might have an empty weight of 6,200 lbs and a GVWR of 14,000 lbs, showcasing their substantial capacity. They are typically equipped with heavy-duty axles, such as two 10,000# axles with electric brakes and dual wheels, ensuring they can handle the significant weight of loaded containers.

Common Industries and Uses

The versatility of conex trailers makes them indispensable across a wide array of industries throughout South Florida:

- Construction: Perhaps the most obvious application, conex trailers are crucial for delivering job-site storage containers, temporary offices, and equipment sheds directly to construction sites. This provides secure, ground-level access to tools and materials, keeping projects on schedule.

- Retail Inventory Overflow: Businesses in busy areas like West Palm Beach and Boca Raton often face seasonal surges or unexpected inventory. Conex trailers can swiftly deliver containers for temporary storage of overstocked merchandise or excess equipment, helping retailers manage their space efficiently.

- Logistics and Distribution: For companies involved in moving goods between warehouses, distribution centers, or even across state lines, conex trailers facilitate the efficient transfer of intermodal containers, streamlining supply chains.

- Government and Municipal Projects: From temporary emergency response centers to mobile equipment storage for public works, government entities rely on the flexibility and robust nature of conex trailers to support various initiatives.

- Healthcare Facilities: During expansions, renovations, or even disaster preparedness, hospitals and clinics might use containers delivered by conex trailers for secure storage of medical supplies or temporary administrative spaces.

- On-site Workshops and Mobile Offices: Ground-level offices, built from converted shipping containers, can be delivered via conex trailers to provide comfortable and secure workspaces on remote sites or during facility renovations. Similarly, specialized containers can be set up as mobile workshops for maintenance crews.

No matter the industry, the ability to transport and deploy secure, robust storage or workspace solutions efficiently is a significant advantage. Explore mobile storage solutions to see how these versatile options can benefit your operations.

How to Choose the Right Conex Trailer Solution

Selecting the perfect conex trailer solution for your needs is more than just picking a size; it’s about matching the right equipment to your specific operational demands, site conditions, and budget. Here at Dash Mobile Storage, we understand that every project in South Florida, from a small renovation in Hialeah to a large construction undertaking in Fort Lauderdale, has unique requirements.

Our goal is to help you steer the various options, ensuring you get a solution that is not only effective but also cost-efficient and safe. This involves considering several key factors, from the container’s size to the specifics of your delivery site and even whether buying or renting makes the most sense for you.

Key Factors for Selecting Your Conex Trailer

Before you settle on a conex trailer, let’s walk through the critical considerations:

- Container Size (20ft vs. 40ft): The most fundamental decision revolves around the size of the container you need to transport. Standard sizes are 8×20 feet (20-foot containers) and 8×40 feet (40-foot containers). While a 20-foot container might be sufficient for smaller projects or limited space, a 40-foot container generally offers better value and convenience if your storage needs are substantial, as it often requires less effort to manage one larger unit than two smaller ones.

- Weight Capacity Needs: Always consider the Gross Vehicle Weight Rating (GVWR) of the trailer and the weight of your loaded container. A trailer with a 14,000 lbs GVWR and two 10,000# axles is common for robust operations. Ensure the trailer’s capacity comfortably exceeds the maximum weight of your loaded container.

- Axle Ratings (10,000# vs. 12,000#): Higher axle ratings provide greater load-bearing capability and durability. For heavier loads or frequent transport, opting for 12,000# axles over 10,000# axles can offer improved peace of mind and longevity for your conex trailers.

- Towing Vehicle Compatibility: While a 40ft tilt-bed shipping container trailer can often be effortlessly pulled with a 1-ton pickup (especially when empty), it’s crucial to verify your truck’s towing capacity against the loaded trailer’s weight. Overloading is not only dangerous but illegal.

- Delivery Site Access: This is often overlooked but incredibly important. Is your site easily accessible for a large truck pulling a conex trailer? Consider tight turns, overhead obstructions, and ground stability.

- Required Clearance: Conex trailers, especially tilt-bed models, need ample space for safe loading and unloading. For a 20-foot container, you’ll typically need about 60 feet of straight, clear space. A 40-foot container demands approximately 100 feet of straight space. Additionally, ensure a minimum overhead clearance of 13 feet 6 inches for both sizes during delivery. This foresight prevents costly delays and potential damage.

- Ground Conditions: The surface where the container will be dropped must be firm and level. Soft ground can cause the trailer to get stuck or the container to settle unevenly, creating safety hazards.

Buying vs. Renting: A Cost-Benefit Analysis

The decision to buy or rent conex trailers or the containers they carry largely depends on your long-term needs, budget, and desired flexibility.

Benefits of Renting:

- Lower Upfront Cost: Renting requires significantly less initial capital, making it ideal for businesses or projects with fluctuating needs or limited budgets.

- Flexibility for Short-Term Projects: If you only need a container for a few months for a specific project in the Treasure Coast, renting provides the perfect temporary solution without a long-term commitment.

- Maintenance Included: Often, rental agreements include maintenance, saving you the hassle and expense of repairs.

- Scalability: We make it easy to scale up or down, adding or returning units as your project demands change.

Benefits of Buying:

- Long-Term Asset: For continuous, ongoing needs, purchasing a container can be a sound investment, becoming a depreciable asset for your business.

- Full Customization Potential: While rental units can sometimes be customized, owning allows for complete freedom to modify your container with shelving, lighting, HVAC, or specialized security features without restrictions.

- No Monthly Payments: Once paid off, you eliminate recurring rental fees.

At Dash Mobile Storage, we offer flexible billing options for monthly or annual leases for our mobile storage solutions. This allows our valued customers to have convenient and accessible storage on their terms, whether they’re in Miami or Stuart.

Customization and Add-On Options for Conex Trailers

Both the conex trailers themselves and the containers they transport offer a range of customization and add-on options to improve functionality and meet specific requirements.

For the conex trailers, improvements can include:

- Winch Upgrades: A heavy-duty 18,000# electric winch can make loading even the heaviest containers a breeze.

- Toolboxes: Integrated toolboxes provide secure storage for straps, chains, and other essential equipment.

- Pin Locks: Multiple sets of pin locks ensure containers are securely fastened to the trailer during transit.

- Spare Tire/Wheel & Tire Upgrades: Having a spare or upgrading to more robust tires (e.g., 14 ply) adds reliability for long hauls.

- Wireless Remote for Hydraulics: This allows for convenient and safe operation of tilt mechanisms from a distance.

- Suspension & Brake Upgrades: Options like Hutch suspension or 12,000# disc brake axles can improve ride quality and stopping power.

For the conex shipping containers themselves, customization possibilities are virtually endless:

- Lighting Packages: Interior and exterior lighting for visibility and security.

- HVAC Systems: Essential for office containers or those storing temperature-sensitive items in Florida’s climate.

- Custom Paint and Decals: Branding or specific color schemes for your business.

- Shelving and Interior Modifications: To optimize storage and organization for excess inventory or job-site storage.

- Security Improvements: Improved locking mechanisms, surveillance, or alarm systems.

- Restrooms: For mobile office or facility containers.

These options transform a basic container and trailer into a highly specialized tool, perfectly adapted to your operational needs.

Frequently Asked Questions about Conex Trailers

We often get asked common questions about conex trailers and their use, especially from businesses looking for efficient storage and transport solutions in South Florida. Here are some of the most frequent inquiries and our expert answers.

What’s the difference between a Conex trailer and a shipping container?

This is a fundamental question, and understanding the distinction is key! A shipping container, often referred to as a Conex box, is the large, sturdy steel box itself. This is the unit designed for actual storage or for holding cargo during transport. It’s the “box” that keeps your items safe.

A Conex trailer, on the other hand, is the specialized wheeled chassis—the frame with wheels—that is specifically designed to transport that shipping container. It’s the “vehicle” that moves the box. Think of it this way: the container is your mobile storage unit, and the conex trailer is the towable platform that makes that storage unit mobile on land. A “container truck” is then the actual truck that pulls the conex trailer.

How much space is needed to deliver a container with a tilt-bed trailer?

When using a tilt-bed conex trailer for ground-level delivery, sufficient space is crucial for safe and efficient operation.

- For a 20-foot container, you’ll typically need approximately 60 feet of straight, clear space in front of where the container will be placed.

- For a 40-foot container, this requirement increases to about 100 feet of straight, clear space.

In addition to the straight length, you’ll also need a minimum of 13 feet 6 inches of overhead clearance to accommodate the height of the truck and trailer during the delivery process. This ensures the container can be smoothly and safely rolled off the trailer and onto your desired spot without any obstructions. Failing to provide adequate space can lead to delivery delays or even prevent placement.

Can a standard pickup truck pull a conex trailer?

The ability of a standard pickup truck to pull a conex trailer depends heavily on several factors: the weight of the trailer itself, the weight of the container (empty vs. loaded), and, most importantly, the towing capacity of the pickup truck.

Our research indicates that a 40ft tilt-bed shipping container trailer, when empty, can often be effortlessly pulled with a 1-ton pickup. However, once a container is loaded, especially a 40-foot unit, the combined weight can quickly exceed the capabilities of many standard pickups. For instance, a 40′ Gooseneck Shipping Container Trailer from our research has an empty weight of 6,200 lbs and a GVWR of 14,000 lbs. If you’re planning to move a loaded container, you’ll almost certainly need a heavy-duty truck designed for commercial hauling.

Always, always check your specific truck’s towing capacity (found in your owner’s manual) and compare it against the Gross Vehicle Weight Rating (GVWR) of the conex trailer plus the weight of the loaded container. Safety should always be the top priority, and exceeding towing limits is dangerous and illegal.

Conclusion: Your Next Step in Mobile Storage

Conex trailers are more than just a means to transport a steel box; they are a vital component in modern logistics, offering unparalleled versatility, efficiency, and security for a myriad of applications. From their humble beginnings as military innovations to their current role as the backbone of global trade and local business operations, conex trailers have proven their worth time and again.

We’ve explored how these specialized trailers, whether they are hydraulic tilt-beds making ground-level deliveries a breeze or gooseneck designs providing stable long-haul transport, empower businesses to manage their storage and transport needs effectively. We’ve also digd into the robust construction that ensures durability, the critical safety features that protect cargo and personnel, and the various customization options that transform a simple container into a custom solution.

Choosing the right conex trailer solution involves careful consideration of container size, weight capacity, towing vehicle compatibility, and site access. Whether buying for a permanent asset or renting for flexible, short-term projects, understanding these factors ensures you make an informed decision that aligns with your operational goals and budget.

Here at Dash Mobile Storage, we pride ourselves on bringing quality and reliable services to South Florida. We understand the unique demands of businesses and residents across the Treasure Coast, Miami, Hialeah, West Palm Beach, Stuart, Fort Lauderdale, and Boca Raton. Our commitment is to provide timely and reliable delivery of storage containers, ensuring your mobile storage needs are met with efficiency and professionalism.

Don’t let logistics be a bottleneck for your next project. Equip yourself with the knowledge and the right conex trailer solution to keep your operations moving smoothly.

Find the perfect conex shipping container for your project and experience the convenience and accessibility that mobile storage can offer.